Scaffolds loaded with osteogenic factors improve the therapeutic.

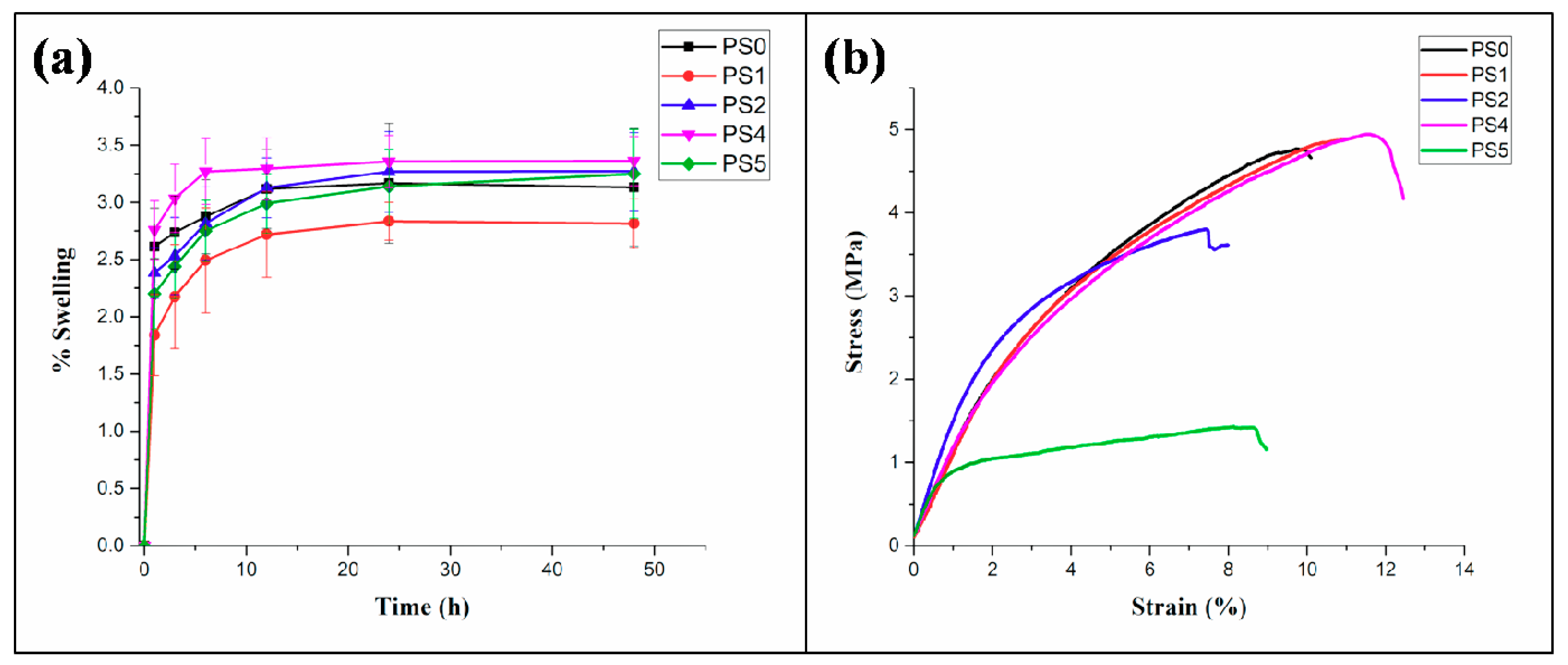

Resulting from the collagen's biocompatibility, the as-prepared scaffold possessed better biological efficacy to promote cell attachment and penetration since the cells mainly contact with the fiber's shell. The incorporation of dual release kinetics to such delivery devices further adds to their applicability. Biomaterial science increasingly seeks more biomimetic scaffolds that functionally augment the native bone tissue. The core/shell fiber can bring many advantages to the scaffold by acquiring PCL and collagen's strong point and overcoming their weakness. SC nanosheets with excellent photothermal conversion efficiency (46.3 ) in the NIR-II. Cell infiltration studies, computed tomography and histomorphometry demonstrated that HAp/PCL NPs-LCS-FD afforded osteoconduction, biodegradation, biocompatibility and bone healing in rabbit tibial model, acting as a template for new bone formation. Bone tissue engineering is the most promising technology for enhancing bone regeneration. The development of drug delivery systems with microencapsulated therapeutic agents is a promising approach to the sustained and controlled delivery of various drug molecules. Herein, we fabricated a coreshell scaffold by printing -tricalcium phosphate (-TCP)/SrCuSi 4 O 10 (SC) nanosheets composites as the shell of the hollow filaments (denoted as hTCP/SC) and inhaled DOX loaded gelatin as the core of the filaments. The developed HAp/PCL NPs-LCS-FD also demonstrated double-ranged pore size, interconnected porosity and efficient mechanical stiffness and strength, favorable for osteoconductive actions. Fabrication and Characterization of Chitosan/ Polycaprolactone Core-Shell Nanofiber Scaffold Containing Platelet-Rich Fibrin by Coaxial Electrospinning. Novel composite freeze-dried, loaded-core scaffolds, HAp/PCL NPs-LCS-FD exhibited controlled swelling and maintained structural integrity for 28 days. Scaffolds were fabricated by 3D printing adopting a biphasic core/shell geometry, where the core phase of the scaffolds was reinforced with HAp/PCL NPs the scaffolds were then freeze-dried. The printing technique was optimized for ink printability and viscosity and crosslinking parameters, where a biopolymeric blend of gelatin, polyvinyl alcohol and hyaluronic acid was developed as innovative plain polymeric ink (PPI). The results showed that the porosity, water retention time and water vapor permeability of the 3D-PT-P/GM scaffolds increased to 1.6 times, 21 times, and 1.9 times than. In this work, extrusion-based 3D printing was employed for the realization of osteoconductive composite biopolymer-based hydrogel scaffolds reinforced with hybrid bioactive hydroxyapatite/polycaprolactone nanoparticles (HAp/PCL NPs) for osteoregeneration. The nanofibers in the scaffold exhibited distinct core-shell structures with Gelatin methacryloyl (GelMA) hydrogel as the shell and Poly (D, L-lactic acid) (PDLLA) as the core. The versatility of 3D printing has rendered it an indispensable tool for the fabrication of composite hydrogel scaffolds, offering bone biomimetic features through inorganic and biopolymeric components as promising platforms for osteoregeneration.

0 kommentar(er)

0 kommentar(er)